Custom Cast Aluminium & Iron Casting Services

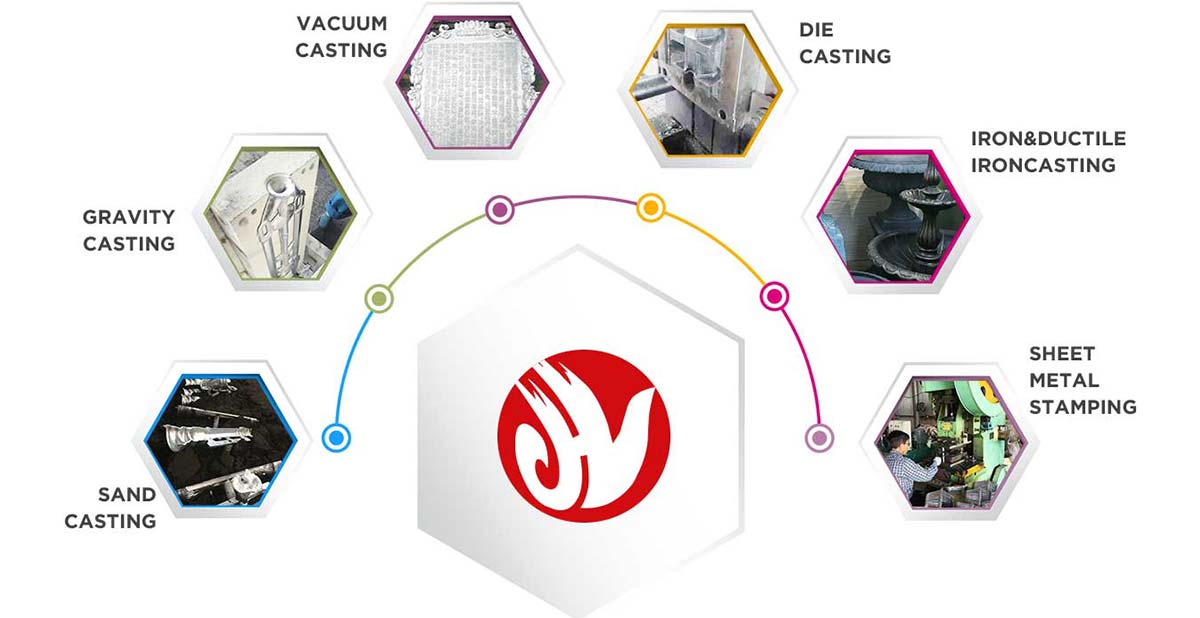

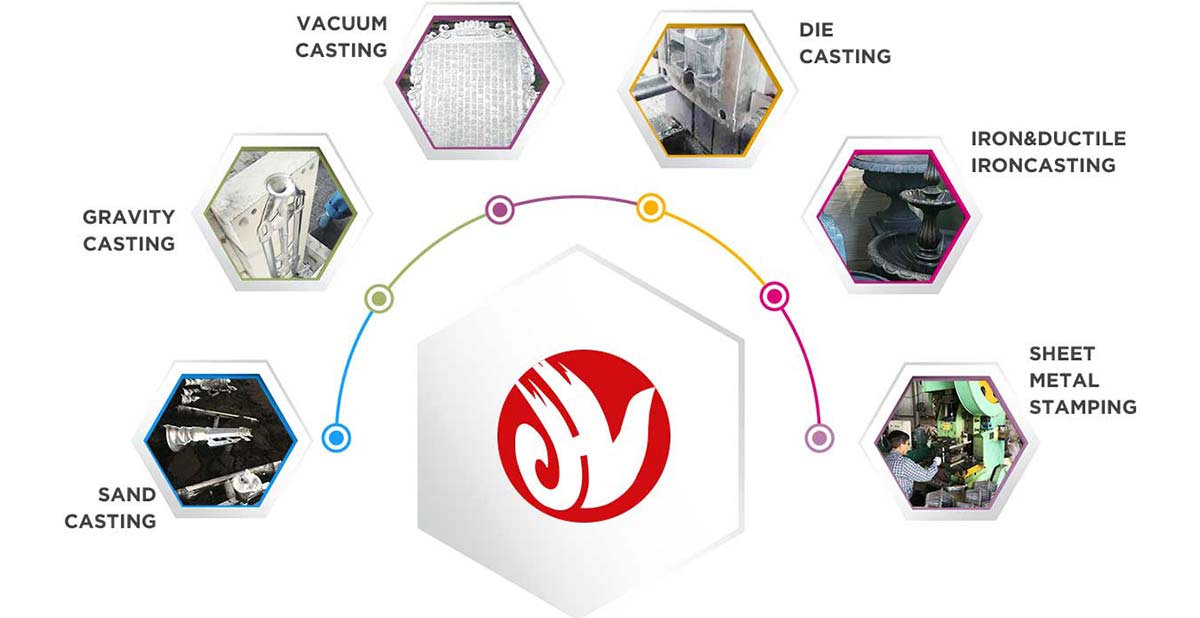

We provide comprehensive casting solutions tailored to meet the demands of modern industrial applications. As a trusted manufacturer, we specialize in both metal casting solutions and advanced cast aluminium solutions, offering custom production, rapid prototyping, and mass manufacturing for global clients. Whether you require high-precision parts or complex geometries, our engineering expertise and production capabilities ensure superior performance, consistent quality, and timely delivery.

What Conditions Can Our Custom Castings Meet?

1. We support intricate shapes, traditional or modern styles, and artistic patterns through precision CNC pattern making and advanced mold design.

2. Suitable for long-term outdoor use in humid, coastal, or high-UV environments. Achieved through material selection (e.g., aluminum alloys, coated ductile iron) and surface treatments (e.g., powder coating, hot-dip galvanizing).

3. Our ductile iron and reinforced aluminum castings are engineered to handle mechanical stress, ideal for gates, railings, and functional components.

4. We ensure tight tolerances (up to ±0.5 mm), enabling seamless installation with other building materials or systems.

5. Offering casting in various metals including gray iron, ductile iron, aluminum (A356, A380), bronze, and others to meet aesthetic, structural, or budget constraints.

Request a Custom Casting Quote

Cast Metal Product Customization Guide

| Product Type | Recommended Material | Corrosion Resistance | Strength | Weight | Notes |

|---|

| Garden Gates | Ductile Iron / Cast Aluminum | ★★★ (with coating) | ★★★★ (Iron) | ★★ (Aluminum lighter) | Iron for strength, aluminum for decorative lightweight gates |

| Decorative Fences & Railings | Cast Iron / Cast Aluminum | ★★★ | ★★★★ (Iron) | ★★ | Aluminum preferred in coastal areas; iron for classic heavy-duty use |

| Lamp Post Bases | Cast Iron / Ductile Iron | ★★ | ★★★★ | ★★ | Strong base needed; powder coating recommended for outdoor use |

| Mailbox Stands & Garden Posts | Cast Aluminum / Iron | ★★★★ | ★★★ | ★★★ | Aluminum is rust-resistant and easier to install |

| Garden Furniture Components | Cast Aluminum / Bronze (optional) | ★★★★ | ★★★ | ★★★ | Aluminum is corrosion-resistant, bronze for high-end applications |

| Decorative Wall Panels & Ornaments | Cast Aluminum / Cast Iron | ★★★★ | ★★ – ★★★ | ★★★ | Aluminum ideal for complex, artistic patterns |

| Structural Support Components | Ductile Iron / Steel (on request) | ★★ | ★★★★ | ★ | Ductile iron provides strength for load-bearing parts |

Cast Aluminum:Lightweight, corrosion-resistant, ideal for decorative outdoor parts. Suitable for complex designs and coastal environments.

Cast Iron (Gray Iron):Cost-effective, heavy, classic appearance. Requires coating to prevent rust.

Ductile Iron (Nodular Iron):Stronger and more impact-resistant than gray iron. Suitable for gates, posts, and functional parts.

Request a Custom Casting Quote

Key Features:

1. High strength-to-weight ratio

2. Excellent resistance to corrosion and heat

3. Suitable for thin-walled and complex designs

4. Ideal for automotive, electronics, HVAC, and machinery components

We support full OEM and ODM aluminum casting services to help you reduce costs, accelerate development, and ensure quality across your supply chain.